Contributor: Don Kranbuehl, FAIA

Architects are realizing the 2030 Challenge is no longer just about tracking predicted Energy Use Intensity (pEUI) and operational carbon (the carbon emitted from building mechanical systems). In the next 10 years, it will be critical to also make great strides in reducing embodied carbon (the carbon emitted from the interior and exterior materials that are used to construct buildings). Embodied carbon emissions make up a large amount of greenhouse emissions from the built environment and have greater potential to have an immediate impact on reducing the effects of climate change. Overall, building energy sources and their materials account for nearly 40% of all global emissions. However, over the next 10 years, approximately 72% of the carbon emitted from new construction will be from embodied carbon. Those metrics alone make it undeniable that as designers, we have a role and responsibility to mitigate environmental impacts by working with nature to develop resilient, sustainable, low carbon projects.

Driven by this social imperative, we are evolving the way we design with the addition of new tools and software to track performance metrics. At Clark Nexsen, we have Integrated Design Leaders who work with our Building Science Group to analyze and provide insight into how to track and reduce pEUI and embodied carbon. Many firms are on a similar path, but figuring out how to create the right internal system that will help designers meet performance goals is the key. Here’s how we’re approaching it:

Defining Integrated Design

We refer to our methodology as “Integrated Design,” which put simply means our different disciplines converge, research, and develop innovative solutions. Our approach is holistic — we design systems, select materials, and consider the site and infrastructure systems in ways to find synergies between building systems that minimize cost but maximize energy conservation, support occupant well-being, and minimize environmental impact.

Similar to the function of third-party certification programs, design firms looking to achieve the highest possible levels of project performance must establish their own process software infrastructure and “roadmaps” to guide the sustainable design process. These tools form the foundation for design teams to intuitively practice integrated design by becoming a seamless component in accounting and project management systems.

Leveraging Our Building Science Group & Taking on Carbon

Two years ago, we established our Building Science Group. Building science is all about energy modeling, improving project performance, and gathering data so we can continue to provide continuous energy analysis throughout the design process. Since its creation, this group has been integral to improving EUI outcomes. It provides full-time access to energy modeling from concept design through construction documents. Our process software infrastructure complements this effort by compiling the data provided and turning it into a readily-accessible resource for future design efforts.

As building science is evolving within our practice, we are also integrating tracking the carbon impacts of our work — both embodied and operational. We have committed to the 2030 Challenge and will now also be tracking embodied carbon moving forward to address this key aspect of global warming. The goal is to reduce embodied carbon by 50% by 2030 in order to stay on track to keep global warming below 1.5 degree Celsius. As a part of our performance-based design process, we track energy, water, materials, habitat reduction, and embodied carbon through our Vision software and our Revit-based Project Goals sheet. The building science analysis tools for tracking carbon now include Tally and EC3, and coupled with our system for specifying low carbon materials and structural systems, will help considerably over the next decade.

Case Studies

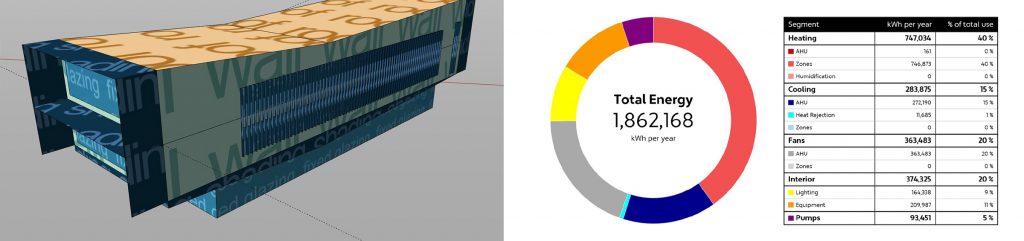

The use of energy modeling during the design of Ferguson’s Headquarters 3 in Newport News, Virginia, played a key role in informing our design decisions. Ultimately, the new facility is tracking 70% pEUI reduction compared to the AIA 2030 baseline.

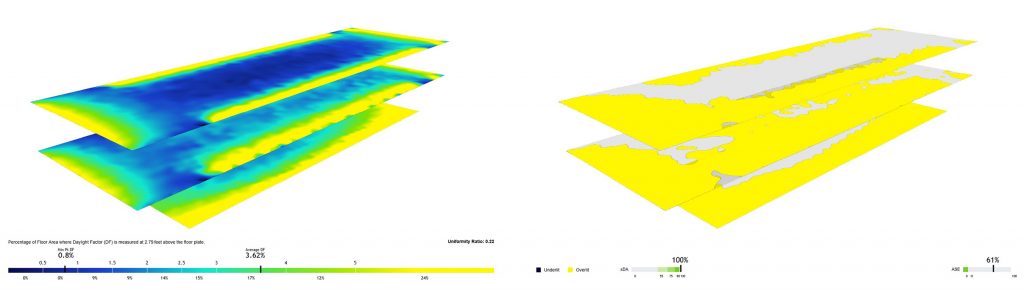

We achieved this projected reduction through both architectural and system solutions. The building’s narrow footprint paired with open office layout will allow daylight to penetrate through to the building core, while the selection of glass with a low solar heat gain coefficient and external sun shades reduce the load on mechanical and electrical systems. Both the heating and cooling systems have a high degree of controllability and include features such an energy recovery ventilator and thermal storage that shifts electrical demand for cooling to off-peak nighttime hours.

At Alamance Community College in Graham, North Carolina, early analysis of the site for its future Biotechnology Center of Excellence, daylighting, and environment is informing the ongoing design phase. A preliminary energy analysis factored in the anticipated end uses of energy in the building, which are being further refined and modeled as the project progresses. The most important step for this project was to right-size the building and program to make the building as efficient as possible. In terms of energy, the daylighting analysis indicates ample opportunity for natural light throughout most of the building, while glare management will be needed on the east and west sides. The design team is exploring a variety of shading options to mitigate glare and control solar heat gain.

The early energy analysis indicates that a focus on glazing thermal performance and limiting glazing areas will have a meaningful, positive impact on energy performance. Internal plug loads and ventilation rates will have a significant impact on energy consumption as well. The strategies being explored include air-to-air energy recovery, reduced fume hood face velocities, use of ductless fume hoods where feasible, and separation of spaces requiring higher air changes (labs/research zones) from those with lesser requirements (offices, documentation areas).

For the embodied carbon analysis, we will be using EC3 and Talley to examine the embodied carbon in both the structural system and the interior and exterior materials. We will explore various structural systems including mass timber and a high recycled content steel structure and look to minimize the use of cement in the foundations. From an architectural materials standpoint, we will look to avoid XPS foam insulation, reduce the amount of CMU as much as possible, and specify local, regional, high recycled content materials as much as possible.

At the end of the day, data and what we do with it is how we as an industry can improve project performance. Individually, we can only make an incremental impact. Together, using an effective holistic and collaborative design process across each firm, we can radically reduce the impact of the built environment on climate change.