Cast-off lumber is just part of the cost of doing business for the timber industry, sold for pulp, wood chips, or otherwise discarded. It’s the lemon peel nobody wants or the broccoli stem nobody seems to care for. But what if we could do something useful with timber industry waste—upwards of 55% of harvested wood that’s deemed unusable for lumber because it’s a little (or a lot) irregular, damaged, or undesirable?

That’s the question Kyle Schumann and Katie MacDonald asked who—along with their project partners at the UVA School of Architecture, alumna Abigail Hassell, the school’s FabLab team, the UVA Sawmilling folks, and students—wanted to do something more with the stuff everyone thinks less of. That’s the idea behind their project “Tangential Timber,” which recently received an Honorable Mention in the Small Project category by AIA Virginia in its annual Honors and Awards program.

Using more of what’s around is kind of a sweet spot, research-wise, for Schumann and MacDonald, whose firm After Architecture was the subject of an Inform piece last year that focused on their award-winning project “Homegrown,” a small room constructed of walls made of invasive plants and yard waste and installed at the Knoxville Museum of Art in 2020.

Like Tangential Timber, “Homegrown” boils sustainability and decarbonization down to two facts that are true in virtually every arena: we manufacture more than we need as global industries and we ignore a lot of what nature has to offer as a species. Resourcefulness is a good virtue and a good practice, say Schumann and MacDonald, and it’s probably a lot more scalable than we realize. Call it upcycling. Call it recycling. Call it MacGyver’ing.

Call it whatever you like. But, resourcefulness and doing more with what you have is a scalable idea that works for an architecture school just as well as a C-suite’s P&L report.

This year, Tangential Timber was recognized in AN’s Best of Design Awards, as well, put on by The Architect’s Newspaper, on the heels of last year’s R+D Award from Architect Magazine—both offering a well deserved boost to one of the most creative and principled firms in Virginia. Here’s what Schumann and MacDonald had to say about what’s quickly becoming one of the most memorable projects of the last couple of years.

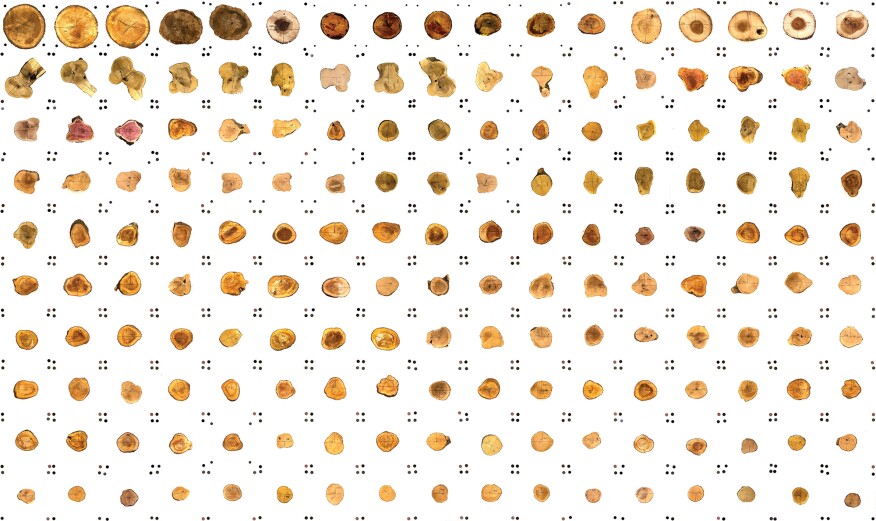

You developed what you’re calling a “low-tech, parametric digital imaging workflow” to photograph and trace the cookies—or wood rounds—in 2D and then translate them into 3D models. What exactly does that mean?

KS: Why we’re doing this is we’re interested, in general, to leverage digital tools to make them easier to use across our projects. In this case we had 164 cookies used in the final construction—when you have that many pieces, if you scan them individually, there’s a lot of data there and it quickly becomes difficult to use them when you’ve got all that data in Rhino on a laptop. So, we wanted to use a lower-data way to do this. We photographed each cookie and processed the image using custom software, which automatically scales it, corrects for perspective, and extrudes it to produce a simple 3D digital model. This process means that we can work with hundreds of pieces of digitized material in the same file with ease. It’s the digital version of Incan stonework—and after the scanning process, there are different Grasshopper scripts that are run through Rhino. We modeled the vault shape to make sure it was a compression structure. We arrayed the cookies into a grid, side by side, and then used spring simulations to pull those cookies together with some overlap—a couple of inches—to produce joinery. Once we have that in 2D, we translate it back into 3D form and then make the joinery.

KM: The expression of the geometry is related to how engineers have created compression structures. We were interested in how the cookie became a masonry block. As Kyle alluded to Incan structures, we also zeroed in on masonry compression structures as a precedents. Rather than thinking about stone, we thought about wood. We were looking at Heinz Isler’s hanging fabric structures as one model.

KS: On one hand, we found that the timber industry is materially efficient—offcuts are broken down into chips and composited into things like oriented strand board. But, then, when you use formaldehyde glue, it makes it hard to deal with that material at the end of its life. So, we want to figure out how to use technologies in a new way to make these materials accessible to everyone to use, and to leverage the embodied intelligence of materials like bamboo, native grasses, and timber in a way that’s about incremental change. We see dimensional lumber as being optimized for labor, ease of construction, and codification. I think we can branch out from that with the growing complexity of computer simulations.

KM: We’re also interested in the inventory of tree species being broader than what are usually selected for the production of buildings. We want to broaden the definition of what’s usable or deemed appropriate for construction. There’s an interesting split between dimensional lumber for light-frame construction and the emergence of the mass-timber market, which is about cranes.

It seems that part of architecture school for incoming students is unlearning what they know about materials so they can really understand how those materials work. How do you get students to see things the way you do?

KS: Students were involved in every step of this project, and when we teach, and we’re teaching fabrication, it’s about letting go of preconceptions about materials. We have some abstract exercises to get them to see materials they know differently. We ask them to cut and operate on a log, and they find that the geometry of a log is at odds with most of the tools we have in our woodshops. So, they have to develop tools to overcome the embedded bias that comes with common woodworking machinery..

Do you see this as a scalable solution, since we talked about both this project and Homegrown as prototypes?

KM: We hope this provides a transferable solution about adapting to local tree species, but also adapting to local inputs. This is about taking an inventory of material and assembling it to maximize the geometry and thickness of each piece. The vault is something we’re doing with cookies today, but it could be timber in different orientations, too.

KS: As a prototype, it’s at the far end of the local prototype spectrum. We used logs from UVA Sawmilling, so it’s a hyper-local solution in this case, but it doesn’t have to be.

KM: Following up on Tangential Timber, we’re working on developing tools to deal with non-linear wood. Tools that allow us to respond to the varying qualities of a piece of wood rather than assuming a straight log.

KS: With that, we’ve worked with collaborators to invent a robotic sawmill system that allows us to cut curving and twisting geometries from logs at a large scale. A lot of the work in architecture schools now is with robotic arms, often used in industrial production for cars, but far less common in the production of building products. One of our aims with working with a sawmill as our tool rather than a robotic arm is that it is something that’s deployable and something that the timber industry is already working with—increasing the chances of wide scale implementation. Tangential Timber was a fairly laborious process—time and energy and machining—so we are hoping with the new robotic sawmill to make that easier in the future.

How do you draw others into collaboration with you?

KS: We’ve seen growing excitement in this. The annual conference of Computer-Aided Design in Architecture (ACADIA) just had its meeting recently, and it’s all about digital fabrication and computation and materials—and almost all of those projects have a relationship to climate. So, there’s a lot of excitement about this work and we see people doing it in various ways. One way we try to approach it is to work between a strictly technological view of the work but also valuing design, itself. That’s why we refer to our projects as prototypes. There’s a believability with something you can touch and walk into and even see in a photograph.

KM: The last big thing to upend architectural education—or really to change architectural discourse—was the digital turn and the introduction of digital tools. Some celebrated that with smooth parametric designs. Some see BIM as the big product of that development. But, what we posit is that the biomaterial turn is going to be the next thing—or currently the thing that’s changing architectural education. We’re seeing that evolve really rapidly now. Mass timber really gave that fuel. Today, there’s a real willingness to experiment with it. We have a lot of talented people doing a lot of innovative things in this field, so we’re lucky to be in this space and get to experiment. It’s funny, even submitting to things like AIA awards, a “pavilion” is so outside of what’s commonly recognized, but it’s important to us to present it in this way and to participate in those awards programs. It’s part of the effort to highlight biomaterials and what we feel is an important evolution for architecture.

William Richards is a writer and editorial consultant based in Washington, D.C. From 2007 to 2011, he was the Editor-in-Chief of Inform Magazine.

Project credits:

Tangential Timber, University of Virginia and After Architecture

Principals: Kyle Schumann (Assistant Professor, University of Virginia / Cofounder, After Architecture), Katie MacDonald AIA (Assistant Professor, University of Virginia / Cofounder, After Architecture), Abby Hassell (B.Arch ’22 University of Virginia)

Wall Prototype Students: Abby Hassell, Audrey Lewis, Jacob McLaughlin, Rohan Singh, Abbie Weissman (developed in ARCH 3021: Design Thinking Studio II: Material Cybernetics, taught by Kyle Schumann in spring 2021)

Vault Research Assistants: Sonja Bergquist, Cecily Farrell, Alex Hall, Caleb Hassell, Dillon Mcdowell, Annabelle Woodcock.

Funding: UVA Jefferson Trust Flash Funding Grant; UVA Center for Global Inquiry and Innovation Faculty Global Research with Undergraduates (FGRU) Grant; UVA School of Architecture Dean’s Office.